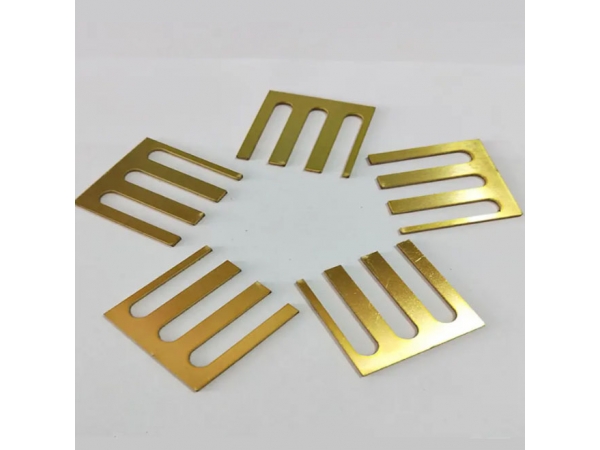

custom precision metal shims

Shenzhen Casignals Hardware Co., Ltd. is specializing in making all kinds of metal shims by photo etching, laser cutting or stamping.

Shim thickness in mm including:

0.01mm, 0.02mm, 0.025mm, 0.03mm, 0.04mm, 0.05mm, 0.06mm, 0.07mm, 0.08mm;

0.1mm, 0.12mm, 0.13mm, 0.15mm, 0.18mm, 0.2mm, 0.25mm, 0.3mm;

0.4mm, 0.5mm, 0.7mm, 0.8mm, 0.9mm, 1mm, 1.2mm, 1.5mm,2mm, 2.5mm, 3mm

When and Why Use Photo Chemical Etching to make your super thin shims?

Photo chemical machining produces burr-free metal shims with none of the deformation that other manufacturing processes can cause. It is a fast, efficient, cost-effective alternative to stamping, punching, laser cutting, and other production methods.

There are essentially no limits to the designs we can work with. No matter how simple or complex your design, we can use chemical etching to produce precision metal shims that perfectly match your specifications. Whether you need a half dozen parts or 100,000, photo chemical machining can produce metal shims with perfect precision and repeatability from the first piece to the last.

We also provide in-house forming, as well as additional secondary services such as plating and heat treating, to add further value to our products. We offer some of the industry’s fastest lead times, low, one time tooling costs, and one of a kind, personalized service. Prototyping services are also available.

Why choose us?

Custom Made

Shims are used in a wide range of applications—from shims used in the landing gear of an aircraft to the shims found in the exhaust systems of NASCAR race cars. Whatever your project or design calls for, we can manufacture it.

We give you complete control over the materials, thicknesses, shape, quantity, and quality of the shims you need. With over 300 raw materials on hand, we can manufacture shims in materials like brass, copper, nylon, stainless steel, PTFE, and much more. We can even manufacture custom shims with outside diameters ranging from .04” up to 6”. Our shims are also offered in ultra-thin dimensions all the way down to .0005”.

Made to Precision

We ensure that each of our custom shims are made with perfect precision, every time. We understand that technology is constantly changing, and we seek to stay ahead of the curve by utilizing only the latest manufacturing methods combined with state-of-the-art equipment.

Rapid Delivery

Working on deadlines means that you need your custom-made shims in a hurry. This is why we offer some of the fastest delivery times available in the industry. With our in-house tool and die shop, we have the capability to produce your tooling in a matter of hours.

Don’t wait. Contact us today to place your order for custom and precision shims.

Contact: Selina Leung

E-mail: Selina.L@casignals.com

Skype: Julid2012

Wechat & Phone Number :+86-15899795027