How Does Photo Etching Provides Solution for Security industry

Photo etching, also known as photo chemical etching, uses a photo-reactive resist to manufacture metal parts with high precision. Photo etching is one of the latest technology, The process is used to make resistive, complex, and high tolerant metal parts which other process (such as water jet cutting, laser cutting, die-cutting, etc) can not achieve. The process is considered a superior method as compared to other methods. It offers multiple benefits.

The photo etching method can be used with a wide range of raw materials, namely, stainless steel, copper alloy, brass alloy, nickel, titanium, chrome, aluminum, etc. Through this process the material/metal can be customized based on the desired dimensions and properties. The method has a range of diverse applications. They are extensively used in aerospace, automotive, electronics, medical, industrial automation, optical, decorative, circuitry, etc.

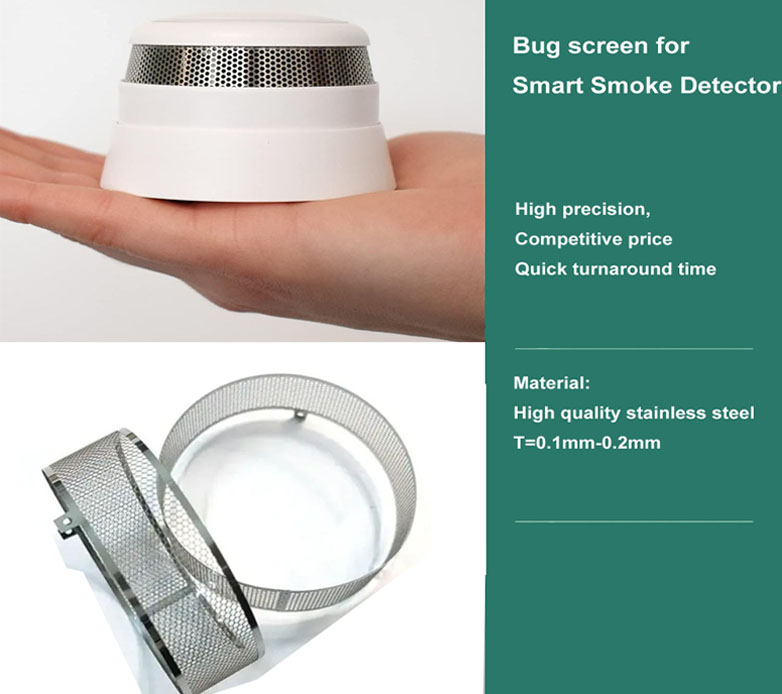

As mentioned, photo etching is a widely used method. Its precision and accuracy provide it an edge over other methods. The method is suitable for the photo etching of metal components which are used in the security industry, especially for the Smart Smoke Detector and the Gas Leak Detector Portable . We can make the stainless steel bug screen or dust screen which are used as part of the smoke detector.

Advantages of photo etching to make the bug screen for smart smoke detector

1 、Improve Precision

The precision of the process is significantly enhanced through the application of photo etching. Photochemical etching can be used with materials as thin as 0.0003 inches. Holes of size as small as 0.004 inches and edges can be made within ±10% of a part’s thickness can be made.

2、Large Volume Production

On short notice, large volumes of parts can be put into production. The process allows higher flexibility with the extension of the work.

3、High Complex Production

The Security industry involves very complex components that are not easily manufactured through other methods. This method of photo etching has revolutionized the Security industry. Bug screens are first designed in AutoCAD. Later the design is applied through this process, and components of great complexity can be easily manufactured. The quality of the parts is also improved through photo etching.

4、Lower Production Cost

The components are manufactured at a reduced cost. This is probably the biggest advantage of this process. Photochemical etching is more cost-effective than most of the other methods.

5、Faster Production

The processing time is made faster. Very complex components are made within a single day. So, the rate of production has been significantly enhanced. This reduction in processing time also affects the cost of production. An etch rate of as fast as 0.001 inches per minute can be achieved.