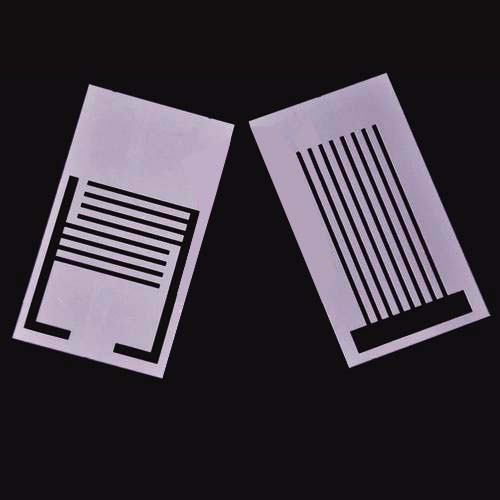

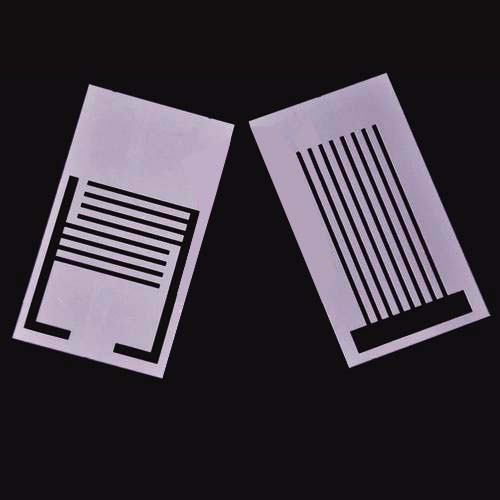

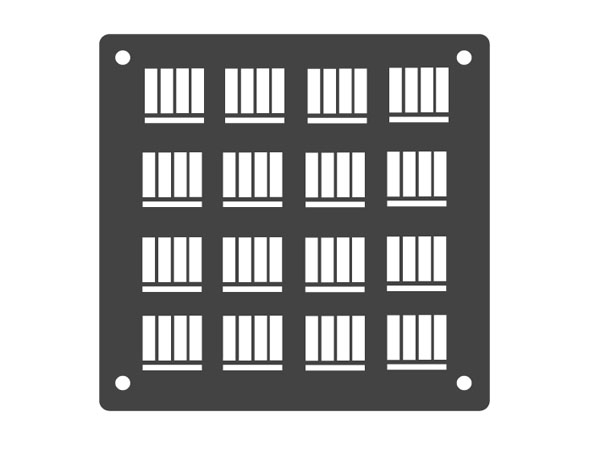

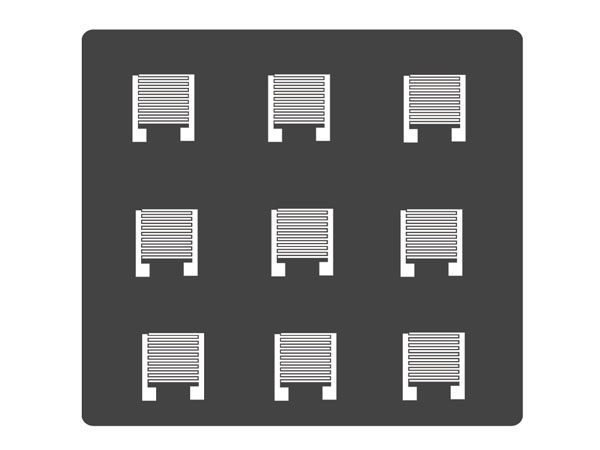

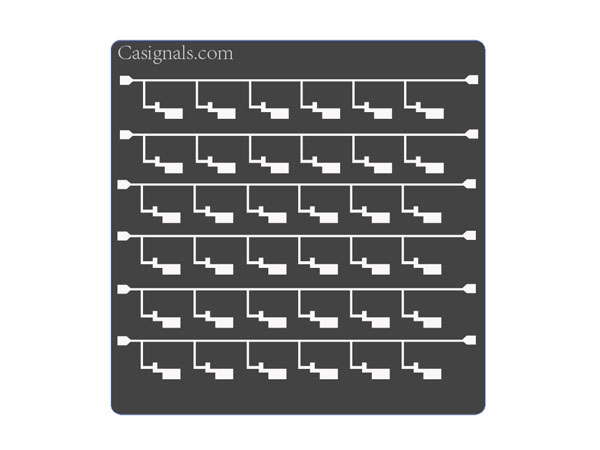

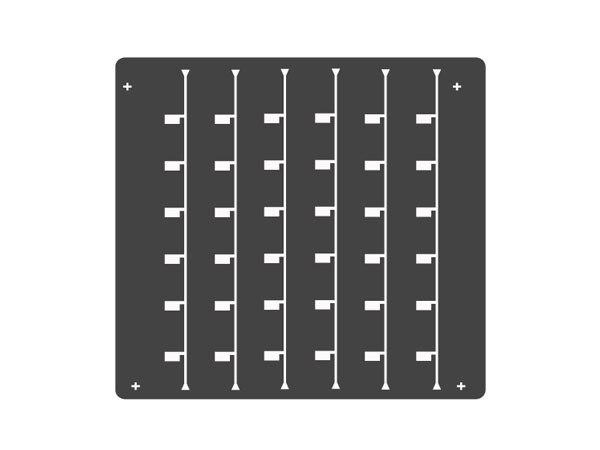

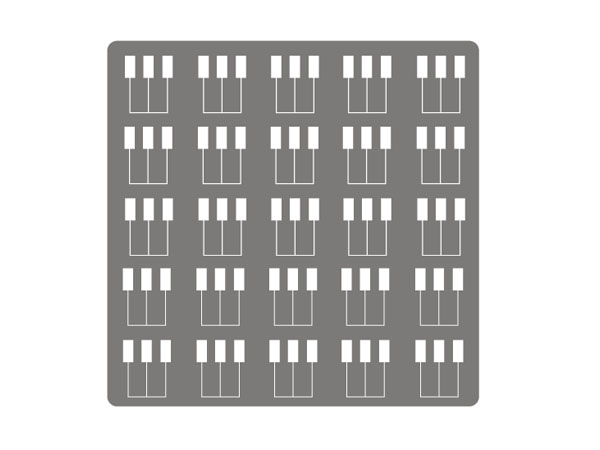

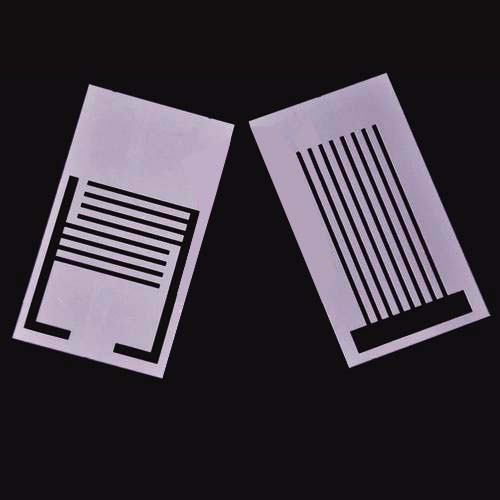

A shadow mask is a micro machined template (typically a laser cut or chemically etched thin sheet of metal) use to deposit material onto a substrate. Deposition mask techniques are used in a wide range of vacuum-chamber evaporation and sputtering processes to fabricate both simple and complex micro-engineered electronic components and products. They are increasingly being used to deposit inks onto substrates during the manufacture of flat panel displays or for the deposition of metal electrodes on polymer, glass or ceramic substrates.

| Product Name |

Shadow Mask, Deposition masks |

| Material |

Most are made of stainless steel, if you need to use other kind of metal material, please tell us |

| Thickness |

0.002" up to 0.020" (0.05mm, 0.1mm ,0.2mm, 0.25mm, 0.3mm and 0.5mm), or at customer‘ request |

| Maximum size |

900*500mm |

| Lead time |

2-5 days |

| Customer Logo |

Can be engraved |

| Drawing format |

CAD drawing in .dwg or .dxf format |

| Payment method |

T/T, Paypal or alibaba trade assurance |

1.

LASER CUT SHADOW MASKS

Casignals offers shadow masks (also known as deposition masks) in a variety of materials, sizes and thicknesses. We use advanced laser technology to fabricate ultra-precision products with burr-free and stress-free finishing.

Ultra-high Precision laser cutting manufacturing - Minimum width of features of 15 um - Aperture tolerance +/-5um

No tooling (lower cost & lead time) Laser engraving available

2.PHOTO ETCHING SHADOW MASKS

Casignals can also make the precision shadow mask by photo chemical etching technology with burr-free and stress-free finishing.lower Tooling cost, complex patterns can be etched.

If you want to make any shadow mask, please contact us today. E-mail : selina.L@casignals.com